The objective of IATF 16949:2016 is to develop quality management systems based on continual improvement, with emphasis on defect prevention and loss reduction throughout the automotive supply chain.

ISO/TS 16949 was created by the International Automotive Task Force (IATF) in order to harmonize the different assessments and certification systems in the global automotive supply chain. This Automotive Quality Management System Standard, hereafter referred to as Automotive QMS Standard or lATF 16949, together with applicable customer specific requirements, and the requirements of 1SO 9001:2015, defines the fundamental quality management system requirements in organizations that manufacture production parts and service parts in the automotive industry.

This Automotive Quality Management System Standard, hereinafter referred to as “Automotive QMS Standard” or IATF 16949″ together with applicable customer specific requirements; the requirements of Standard 1S09001:2015 and Standard 1SO 9000:2015, defines the fundamental requirements of the quality management system in organizations manufacturing production parts and service parts in the automotive industry. As such, this Automotive QMS Standard cannot be considered a QMS Standard on its own but needs to be understood as a supplement to ISO 9001:2015 and used in conjunction with the latter.

The objective of this Automotive QMS Standard is the development of a quality management system that takes into account continual improvement, emphasizing defect prevention and the reduction of variation and waste in the supply chain.

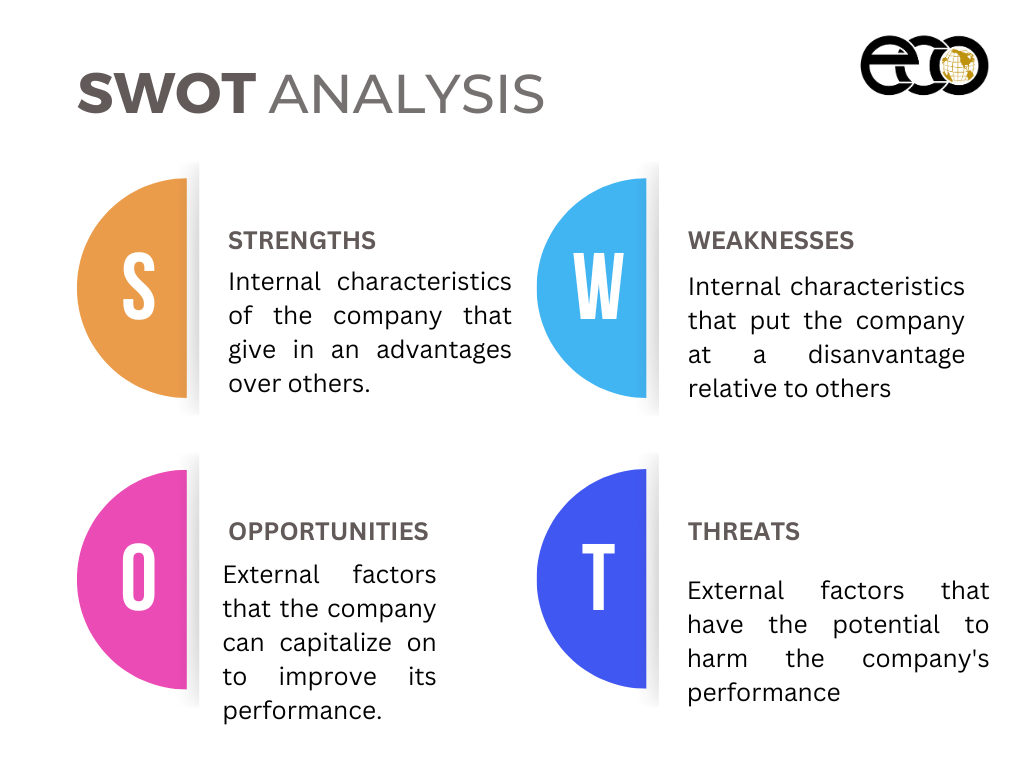

It provides advantages, such as:

- Continuous improvement and increased efficiency of automotive industry processes,

- Increased customer satisfaction.

- Identification and prevention of risks and errors in the automotive supply chain.

- Increased integration with other management systems.